The Design subteam is using a wide range of engineering concepts to design a practical process to implement a light-driven air carbon capture molecule recently created by PhD students in Cornell's Milner Lab. They have created two different process designs and are also focusing on process analysis using techno-economic analysis and life cycle analysis techniques. They are planning proof-of-concept lab work to demonstrate the feasibility of their designs for this project, and are also working on starting up a new project for the upcoming semester.

The mission of the Business and Outreach sub team is to amplify the reach of ESW into the local community and highlight the importance of business in engineering. We accomplish this by intentionally engaging with the community, working with stakeholders, and sharing STEM and sustainability lessons with underserved audiences.

The primary goal of the Research and Development sub-team is to develop innovative nutrient recapturing and repurposing solutions to reduce eutrophication in local waterways. Our projects aim to enhance the engineering skills of our members and improve the environmental conditions of the communities in which we reside.

In September 2021, the B&O team partnered with Cornell Cooperative Extension (CCE) of Suffolk County, NY. The team wrote three lesson plans for a target audience of grades 6-8 on the topics Climate Change and Ocean Health, Biofuels, and Renewable Energy and the Ocean, which will include activities or demonstrations. The educators of CCE Suffolk plan to add these lessons to their brochure and present them to local students at schools, libraries, and their own facilities.

In conjunction with this, the team is also altering the blueprints of the Ithaca PowerHouse that CCE Suffolk can build to repurpose as a portable sustainability museum. The PowerHouse is a tiny home on a trailer that will feature exhibits on the lesson plans the team is writing, and will be brought to the presentations the educators at CCE Suffolk give.

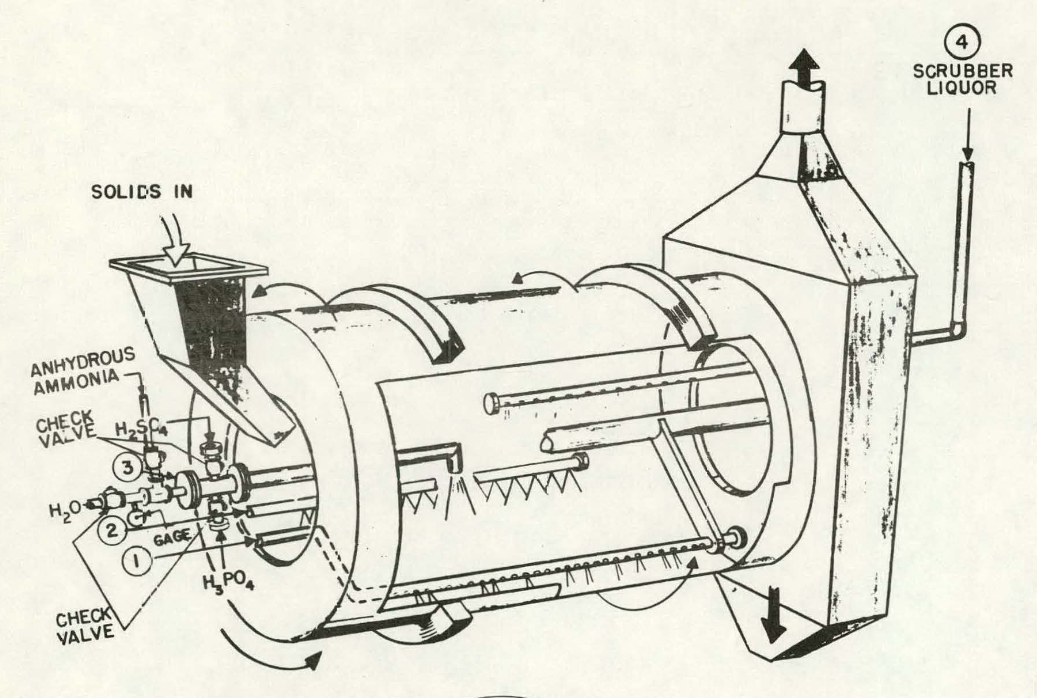

R&D is pursuing a new project on the impregnation of biochar with ammonium phosphate. At a lab scale, R&D will seek to demonstrate the technical feasibility of forming ammonium phosphate in the pores of biochar using aqueous phase reagents. The long term goals of the project are to work with plant science labs to test slow-release fertilizer efficacy in the field.

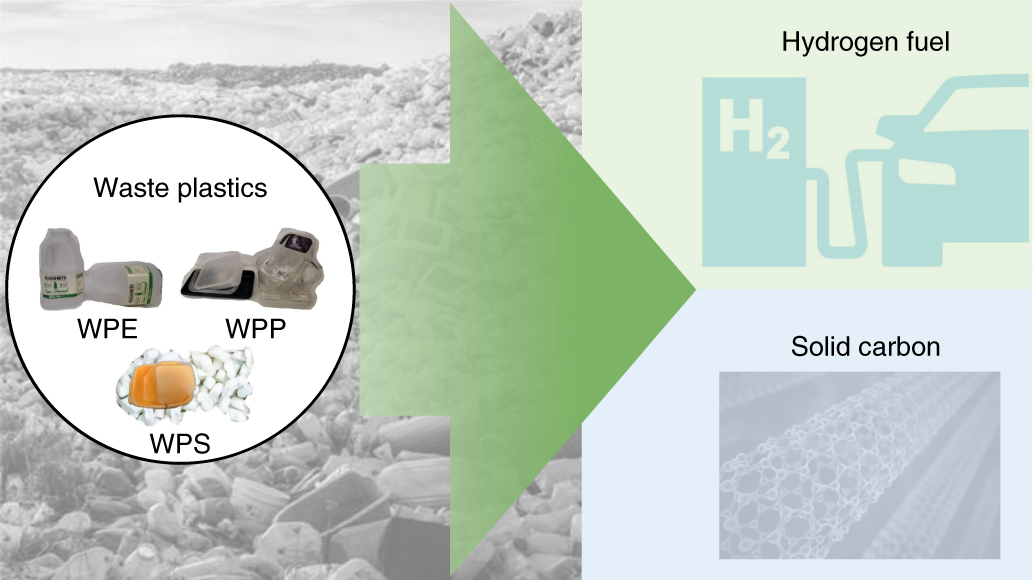

The team will design and test a novel Microwave Catalytic Plastic Deconstruction Reactor that converts plastic waste into valuable carbon nanotubes and hydrogen gas. This reactor will enhance recycling sustainability and economics by reducing energy consumption and costs related to sorting plastics in material recycling facilities, thereby mitigating the environmental impact of plastic waste. This, in turn, encourages the establishment of more recycling facilities, leading to shorter transportation distances, reduced costs, and environmental emissions.

Each semester B&O strives to complete at least one Outreach Event with a local school, the Sciencenter, or the Tompkins County Library to connect with youth throughout Ithaca. Team members lead a lesson on Sustainability and STEM topics with students that includes an engaging activity. The team hopes to educate these youth about the importance of sustainability and inspire them in the STEM field.

The B&O subteam has partnered with the NY Department of Environmental Protection (DEP) to contribute to a large upcoming project to connect residents in New York City directly to farmers along the NYC Watershed. The overall goal of the project is to decrease the environmental footprint of sourcing food while keeping farms economically viable. Our team members are completing a Literature Review on Carrying Capacity Studies to guide the research and methodologies of this upcoming study. Through weekly meetings with project managers and on-site visits along the watershed, B&O members are gaining valuable knowledge and connections.

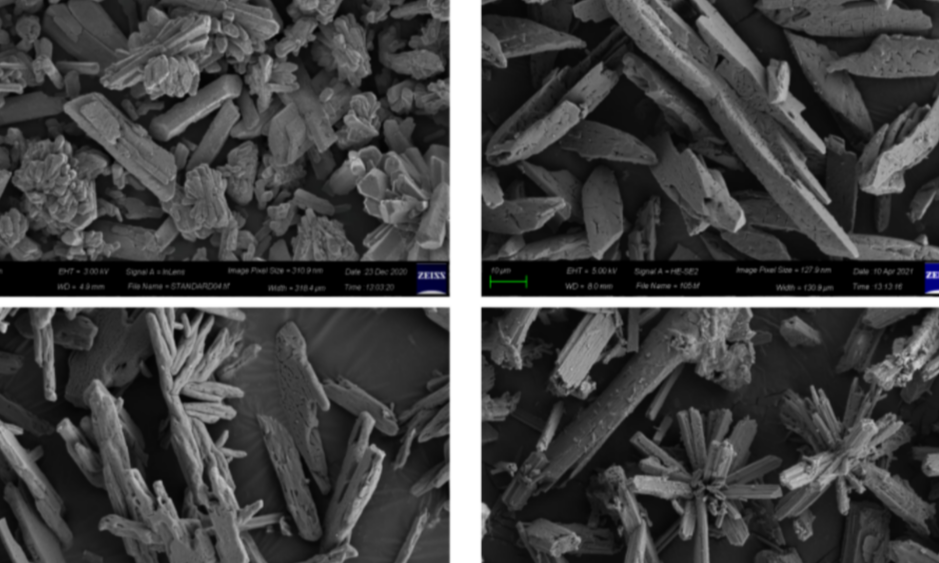

R&D had computationally modeled the formation of struvite, a slow release fertilizer, from waste whey streams. The team learned and used the equilibrium modeling software Visual MINTEQ to complete the analysis. If these methods were found to be cost-effective for their impact on Struvite formation, Acid Whey waste from local dairy processing plants would be collected and in person tests would be conducted to corroborate model results. R&D compiled and analyzed results and published a research paper on this work.

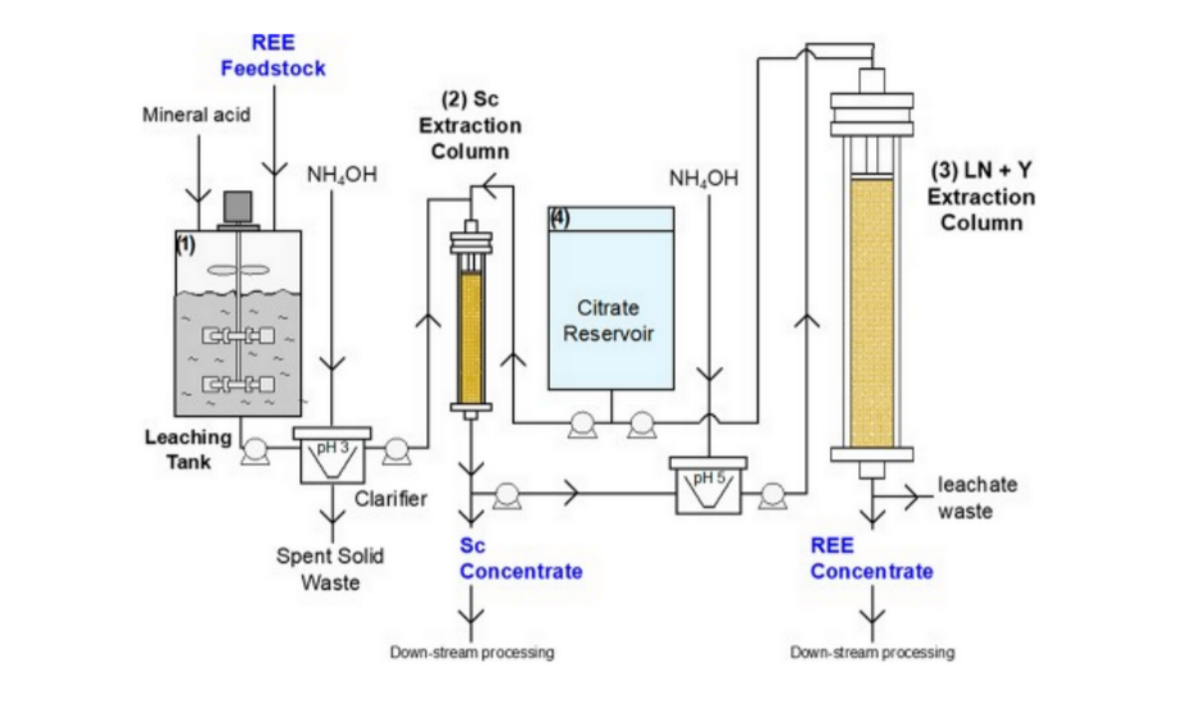

During fall of 2020 up to the spring of 2022, the BioImp subteam had been performing a technoeconomic analysis of rare earth element bioextraction (REE TEA). The project focused on the process of extracting rare earth elements from a source through purification techniques. The traditional method of REE extraction requires high temperatures and pressures, which can be highly energy-intensive. An alternative method involves using microbes that excrete organic acids, This process is more environmentally friendly, but also less efficient, so the team had been working to analyze the economic feasibility of using these microbes. BioImp was working with BEE professor Buz Barstow, who has been working to make the microbes produce more organic acid in order to increase efficiency. The team analyzed whether using these new microbes would make the process more economically feasible.

In the most recent spring 2023 semester, the Bioenergy Implementation subteam created a Continous Biodiesel process capable of powering a campus tractor for an entire summer. This project built off work from earlier semesters, as the Biodiesel Engine Project (BEP) was first created in 2019. The inital goal of this project was to install a Vector System onto a diesel tractor so it can also run on biodiesel, and analyze it with hopes of implementing it in Cornell's 2035 climate action plans. The team uses GREET, a life cycle analysis software, to estimate emissions from pre-combustion processes such as resource extraction and transportation to Cornell. To measure emissions from the tractor, the team has installed a PEMS (portable emissions monitoring system) unit. BEP combined the GREET and PEMS data to perform comparative life cycle analyses on the biodiesel and diesel pathways, using it to analyze the project's practicality before presenting a memo to CTech in March 2021.

Using waste vegetable oil procured from on-campus fraternities, R&D performed batch scale production of biodiesel. From online resources, they learned the various steps necessary for biodiesel production and experimented with different disturbance methods to find the best ways to remove as much soap, the primary byproduct of biodiesel production, from the final product as possible. Through this project they learned extensively about the chemistry behind biodiesel formation and the standards implicit with its use. R&D also studied larger scale biodiesel reactors and had a full-scale model designed, intending on producing larger scale batches for use by Cornell Grounds to power their lawn mowers.

Every year, the Ithaca Area Wastewater Treatment Facility (IAWWTF) processes over 2.5 billion gallons of wastewater from Ithaca and its surrounding areas. This volume of flow carries not only water, but also energy in the form of heat out of the facility. The project team chose to model a heat exchanger and a heat pump using ASPEN and Mathematica, where both heat transfer systems would draw energy from the effluent stream to provide an adjacent room with heat. Both systems pose various comparative advantages and disadvantages, and our final report delved into some of the many variables pertaining to heat transfer devices in the Ithaca Area Wastewater Treatment Facility including operational efficiency, numerical analysis, challenges, cost, and technical feasibility.

In September 2016, the engineers at the Ithaca Area Wastewater Treatment Facility (IAWWTF) asked the ESW Biofuels & Environmental Design team to examine the feasibility of converting biogas into compressed bio-natural gas (bio-CNG) for vehicle fueling. The IAWWTF currently produces biogas from anaerobically digesting waste streams and uses this biogas for cogeneration at their facility. Our team analyzed the possibility of using future capacity of the IAWWTF to fuel TCAT buses once the facility had met its own electricity demand through cogeneration. Our team worked to create a model that compared the greenhouse gas emissions and economic costs of bio-CNG production versus status quo operations of cogeneration in the scenario that the IAWWTF meets their own electricity demand. The team wrote an extensive feasibility report for the IAWWTF that compared these two options, and ultimately concluded that status quo operations may be the most economically favorable and technically feasible option for the facility at this time.

Algae is one of the most versatile photosynthetic organisms, being used for feedstock, fuel and nutrition. Putting them in homes and on roofs can help ease our carbon footprint and reduce circulation of harmful gases.

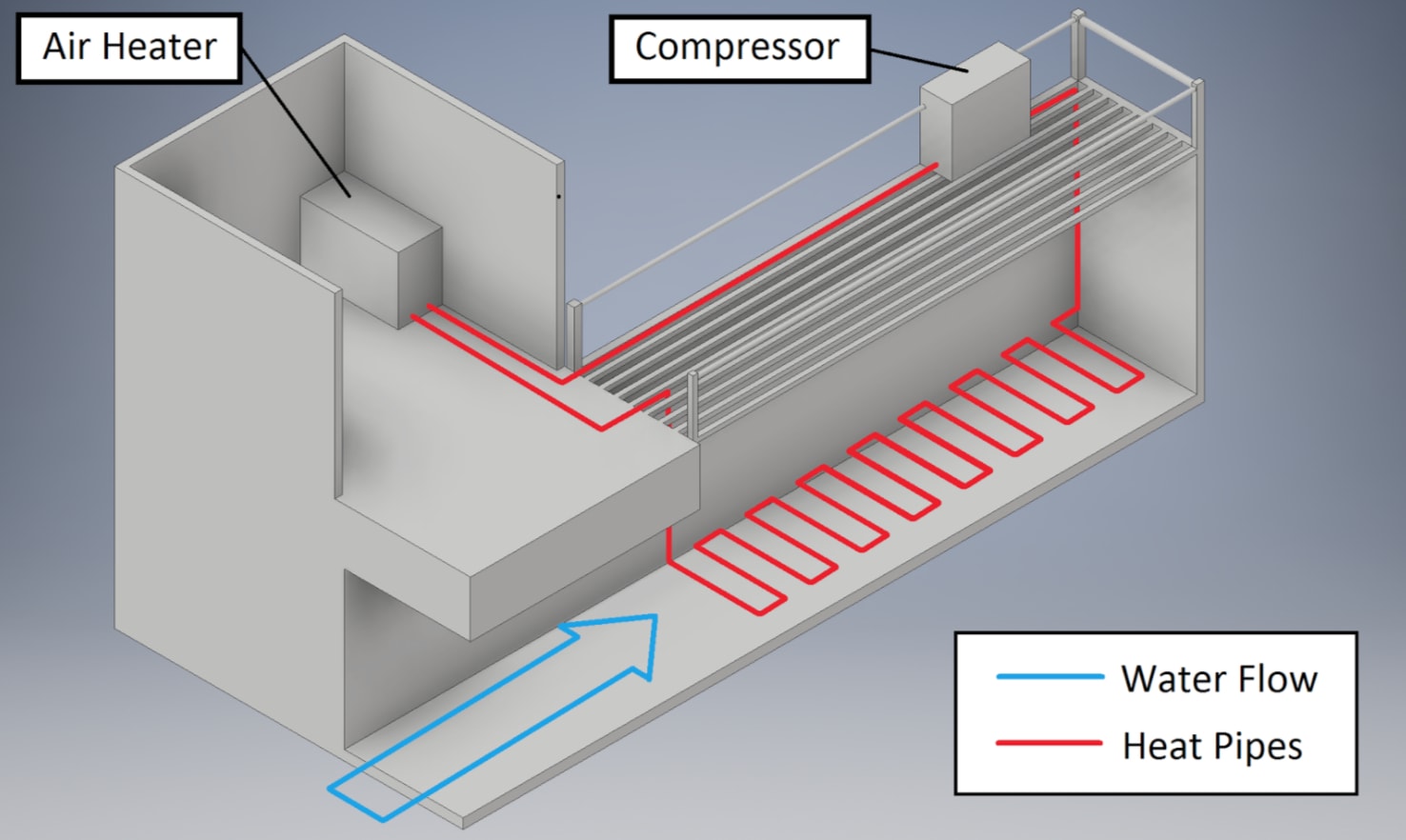

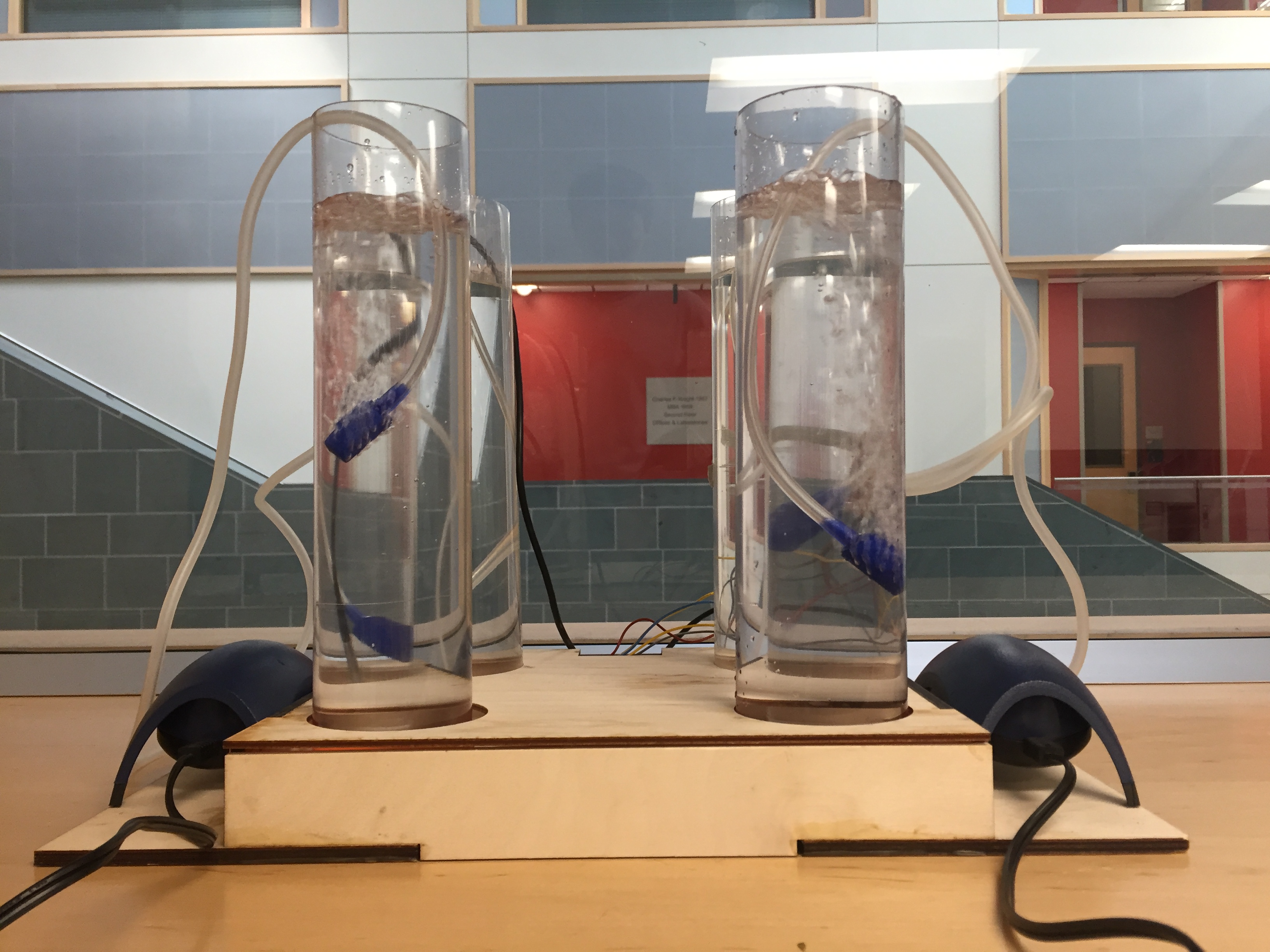

The algal CO2 scrubber project aimed to explore the growth of algae and develop a device to be used in homes with an effluent chimney. Algae in the scrubber would have access to sunlight and carbon dioxide for growth (and thus filter out the gas).

The scubber includes a lasercut wooden base, acrylic housing tubes, two aquarium pump, as well as a colour sensor and temperature sensor to monitor growth. This algae would reach carrying capacity after 2 months, which would ideally be harvested for biodiesel conversion.

The advantages of collecting unwanted fats, oils, and grease (F.O.G.) produced from cooking are two-fold: diverted F.O.G. can reduce pipe-blockage in sewer and septic systems and be utilized as a potential feedstock for biodiesel production.The Business and Outreach team collaborated with the Tompkins County Solid Waste and Recycling Center to submit a design proposal for a F.O.G. collection station. The team reviewed schematics of the design and aided in providing materials for its construction and launch.

On May 30, 2016, the F.O.G. collection station was opened at the Recycling Center, and collects about 1,200 pounds of F.O.G. each month for biodiesel conversion. The team is currently looking to improve the station by designing a heating system to prevent F.O.G. from freezing during the winter months.

University officials originally wrote CURBI, the Cornell University Renewable Bioenergy Initiative, in the late 2000s. CURBI outlined how biofuels could be used to help Cornell reach its climate action plan goals. CURBI was set aside by the University due to a lack of funding for capital expenses and a project champion. CURBI was put on the back burner by the university and has not been revisited on a large scale. ESW Biofuels & Environmental Design spearheaded an effort to revive CURBI and help Cornell achieve its carbon neutrality goals. They have worked with professors, conducted feasibility studies, and analyzed waste streams to convince the stakeholders that CURBI and renewable energy is an investment worth making. While natural gas (Cornell’s main energy source) is cheap, it will be difficult to reignite passion for CURBI on a university level. Potential motivations for Cornell would include an acceleration of its Climate Action Plan, a carbon tax, and better definition of some of the technology CURBI intends to use.

In the fall of 2014, the team built a 1-gallon biodiesel reactor to gain hands-on experience with biofuels. The reactor was made from a plastic vessel with two spouts. The two spouts allowed the team to separate oil from glycerol. The reactor was stirred using an electric drill and was heated using a crock-pot water bath. Many of the other parts for the reactor were made by hand.

After successfully constructing the reactor, the team collected waste vegetable oil from the community. Test batches were run in the reactor, but stirring was too vigorous and emulsified the biodiesel in the glycerol. The reactor was successful in teaching the team about biodiesel generation and giving members an introduction to the steps and challenges involved in generating biofuels. The team plans to revisit the biodiesel reactor in the near future and will complete a more thorough demonstration unit.

B&O is continuing their partnership with Cornell Cooperative Extension (CCE) of Suffolk County on a podcast project, as well as beginning a new partnership with the Shinnecock Indian Nation Environmental Department and the NYS Water Resources Institute. In the podcast, they will discuss Indigenous peoples' perspectives on sustainable engineering and implementing natural solutions as a response to climate change. In December of 2021, the team was awarded a $3,000 Engaged Opportunity Grant from Cornell's Einhorn Center for Community Engagement. Once the podcast is completed, B&O hopes to extend this work to develop engineering solutions to the environmental problems discussed during the recording.

Members are expected to attend the weekly general-body meetings Mondays 6 - 7PM and weekly sub-team meetings.